CNC Turning Services – Precision Machining for Custom Components

In today’s fast-paced manufacturing world, businesses need reliable machining processes that deliver accuracy, speed, and cost efficiency. One of the most widely used and versatile techniques is CNC turning services, which produce precise cylindrical parts for industries ranging from aerospace to medical. By using advanced computer-controlled lathes, CNC turning offers unmatched repeatability and consistency, ensuring every part meets exact specifications. For companies seeking quality parts with tight tolerances, CNC turning is an ideal choice that blends modern technology with expert craftsmanship.

The Role of CNC Turning in Modern Manufacturing

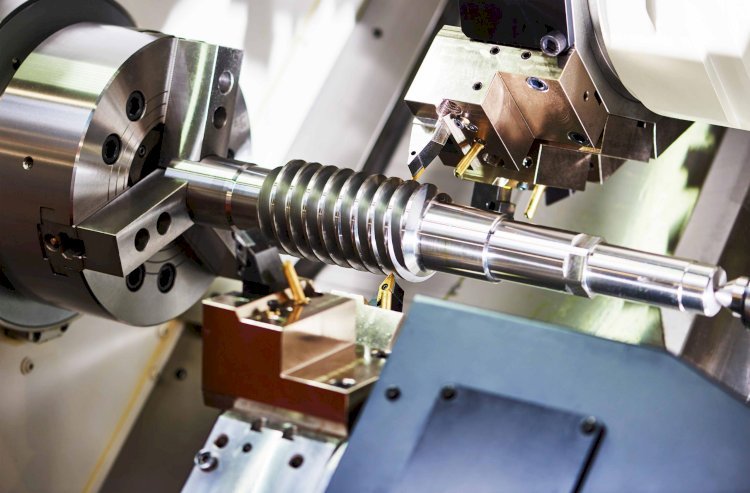

CNC turning is a subtractive manufacturing process in which a cutting tool removes material from a rotating workpiece. This method is particularly effective for creating parts such as shafts, bushings, and threaded components. Its strength lies in its ability to handle a variety of materials including metals, plastics, and composites while maintaining high precision.

The demand for CNC turning has grown as industries require shorter lead times and more complex part designs. With automation, operators can program the machine once and produce large quantities without compromising accuracy. This efficiency makes CNC turning not only cost-effective but also scalable for both prototypes and mass production.

Materials and Applications

CNC turning is highly adaptable, allowing the use of materials such as aluminum, stainless steel, titanium, brass, and engineering plastics. This versatility makes it a preferred solution for multiple sectors:

-

Aerospace: Critical components like landing gear parts and engine housings.

-

Medical: Surgical tools, orthopedic implants, and custom device parts.

-

Automotive: Engine components, gear shafts, and precision bushings.

-

Industrial Equipment: Rollers, couplings, and threaded fasteners.

Benefits Over Traditional Machining

Unlike manual lathes, CNC machines can achieve much tighter tolerances, often within ±0.001 inches. Additionally, the automation reduces human error, improves repeatability, and allows for continuous operation, even overnight. This leads to faster delivery without sacrificing quality.

How CNC Turning Ensures High Precision and Quality

Precision is the foundation of CNC turning. Advanced programming software enables engineers to create exact tool paths, ensuring every cut is calculated and consistent. The integration of real-time monitoring and feedback systems further enhances accuracy.

Advanced Technology in Action

Modern CNC turning centers come equipped with multi-axis capabilities, allowing for complex shapes and features in a single setup. This minimizes the need for repositioning, which reduces errors and shortens production time. Additionally, live tooling options let machines perform milling, drilling, and tapping without moving the part to another station, further improving efficiency.

Quality Control Measures

To guarantee the highest standards, manufacturers implement rigorous inspection processes such as:

-

Coordinate Measuring Machine (CMM) checks

-

Surface finish analysis

-

Dimensional verification against CAD models

These steps ensure that every part meets or exceeds client expectations, which is especially critical for industries like aerospace and medical, where reliability is non-negotiable.

Choosing the Right CNC Turning Service Provider

When selecting a CNC turning partner, companies should look beyond price alone. Factors such as experience, technology capabilities, and quality assurance systems play a crucial role in delivering successful results.

What to Look For

-

Experience Across Industries: Providers with diverse experience can adapt to unique requirements.

-

Modern Equipment: Advanced CNC machines ensure faster production and higher precision.

-

Quality Certifications: ISO standards and industry-specific compliance demonstrate commitment to excellence.

-

Scalability: The ability to handle both small and large production runs without quality loss.

Why Partnering with Experts Matters

A skilled CNC turning provider can help improve product design for manufacturability, recommend the best materials, and optimize production to reduce costs. This level of collaboration transforms the machining process into a true partnership, enabling companies to innovate and stay competitive.

Conclusion

CNC turning remains one of the most essential manufacturing processes for creating accurate, durable, and custom components. From aerospace to medical devices, its versatility and precision make it indispensable. By partnering with an experienced service provider equipped with modern technology, businesses can ensure their parts meet the highest quality standards while benefiting from efficiency and scalability.

What's Your Reaction?