How Do Plate Heat Exchangers Combine Efficiency and Small Size?

Plate heat exchangers have become a well-known solution in industries in which space and efficiency are critical. But what makes them so effective at the same time as preserving a compact layout? In this weblog, we are capable of discover how plate warmness exchangers combine performance and small period, their blessings, and why they are an critical element in modern structures. Along the way, we’ll also comment on the feature of the chrome steel warmth exchanger in improving sturdiness and overall overall performance.

What Is a Plate Heat Exchanger and How Does It Work?

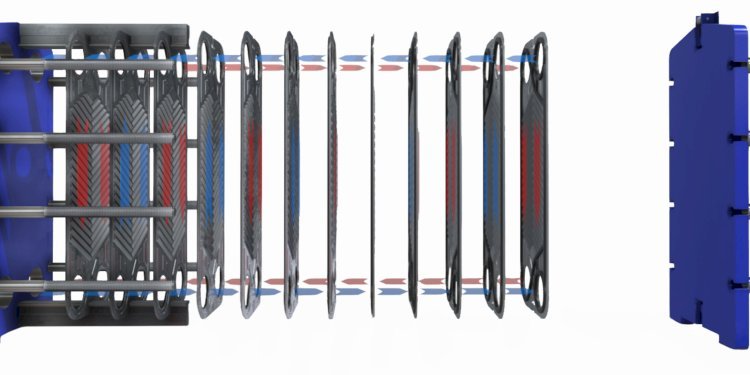

A plate heat exchanger is a type of warmness transfer tool designed to correctly trade heat amongst fluids with out blending them. It includes thin plates stacked collectively, growing more than one channels through which fluids flow. These plates are usually made from long lasting materials like stainless-steel to withstand corrosion and manage immoderate temperatures.

How Do the Plates Improve Efficiency?

The layout of the plates in a plate warmth exchanger is fundamental to its overall performance. The plates are corrugated or ridged, in an effort to growth the floor vicinity for heat transfer. This maximised surface area lets in for better heat alternate in a smaller space, making the unit compact but exceedingly effective.

Why Is Compact Size Important in Modern Systems?

How Does Small Size Save Space?

One of the important blessings of a plate warm temperature exchanger is its compact length. Unlike traditional shell-and-tube warm temperature exchangers, plate heat exchanger require an awful lot much less space to perform. This makes them ideal for industries in which space is restrained, together with marine, automobile, and HVAC structures.

Can Compact Systems Maintain High Performance?

Yes, compact length does now not compromise performance. In fact, the advanced layout of plate warm temperature exchangers guarantees most suitable warmness switch, even in small structures. This is why they're appreciably utilized in excessive-demand packages like power plant life and chemical processing.

What Makes Stainless Steel Heat Exchangers a Popular Choice?

Why Use Stainless Steel in Plate Heat Exchangers?

The use of chrome steel warm temperature exchangers complements durability and resistance to harsh operating situations. Stainless metal in all fairness proof towards corrosion, that is important in industries wherein fluids can be corrosive or perform underneath excessive temperatures.

How Does Stainless Steel Improve Efficiency?

The clean floor of chrome steel reduces fouling (the assemble-up of deposits), making sure that warm temperature switch stays green through the years. This reduces upkeep wishes and improves the general lifespan of the warm temperature exchanger.

How Do Plate Heat Exchangers Save Energy?

What Role Does the Design Play in Energy Efficiency?

The corrugated plate layout of a plate heat exchanger creates turbulence as fluids bypass via. This turbulence improves warmth transfer performance by means of minimising thermal resistance. As a end result, the gadget can perform effectively the usage of plenty less strength.

Can Plate Heat Exchangers Reduce Energy Costs?

Yes, thru optimising warmth switch and decreasing energy intake, plate heat exchangers make a contribution to considerable rate financial savings. Their performance guarantees that industries can maintain high-performance tiers without incurring high operational fees.

Where Are Plate Heat Exchangers Commonly Used?

What Are the Key Applications of Plate Heat Exchangers?

Plate warmth exchangers are utilized in quite some industries, together with:

HVAC Systems: For heating and cooling air in residential and commercial buildings.

Food and Beverage: For pasteurisation and temperature control.

Chemical Processing: To address high-temperature and corrosive fluids.

Power Plants: For efficient heat recuperation and electricity manipulate.

Marine and Automotive: Where area-saving and excessive normal performance are crucial.

Why Are They Preferred in So Many Sectors?

Their compact layout, strength performance, and versatility to special fluids purpose them to a versatile choice throughout various industries.

How Do Plate Heat Exchangers Ensure Easy Maintenance?

Is Maintenance Simpler Compared to Other Heat Exchangers?

Yes, plate warmness exchangers are much less difficult to keep as compared to traditional models. The plates may be removed and wiped easy in my opinion, making sure that the system stays in best scenario with out requiring sizeable downtime.

How Does This Impact Long-Term Performance?

With proper safety, plate warmth exchangers can keep their efficiency for decades. This reduces the want for not unusual replacements, saving fees for industries ultimately.

How Do Plate Heat Exchangers Support Sustainability?

Can These Heat Exchangers Reduce Environmental Impact?

Yes, the strength-inexperienced operation of plate warmth exchangers helps reduce carbon emissions. By optimising warmth transfer, those structures devour less electricity, making them a sustainable preference for industries aiming to decrease their environmental footprint.

Are Stainless Steel Heat Exchangers More Eco-Friendly?

The durability and recyclability of stainless steel heat exchanger make contributions to their eco-friendliness. Stainless metal may be recycled, reducing waste and assisting sustainable production practices.

Why Are Plate Heat Exchangers the Future of Heat Transfer?

What Makes Them Stand Out in Modern Technology?

The ability of plate warmness exchangers to combine performance, compact length, and flexibility makes them an vital element in contemporary warmth transfer generation. Their format continues to comply with upgrades in materials and engineering.

Are There Any Innovations at the Horizon?

Yes, ongoing studies pursuits to beautify the performance of plate warmth exchangers similarly. New substances and designs are being explored to enhance performance and decrease prices, ensuring that those structures stay at the vanguard of business programs.

Conclusion

In stop, plate warm temperature exchangers are an modern solution that combines compact period with high performance. Their design permits for max heat transfer in minimum location, making them best for a huge style of packages. The use of stainless steel warm temperature exchangers similarly complements their durability, power overall performance, and sustainability.

For industries seeking reliable, space-saving, and value-effective warm temperature switch answers, plate warm temperature exchangers offer unrivaled advantages. With ongoing innovations, they're set to play a pivotal position in shaping the future of heat transfer structures.

What's Your Reaction?