How Duct Shop Drawings Transform HVAC Project Efficiency

HVAC systems are the backbone of modern buildings, providing comfort and air quality that occupants depend on daily. Yet behind every successful HVAC installation lies meticulous planning that often goes unnoticed. The difference between a project that runs smoothly and one plagued with delays, cost overruns, and performance issues frequently comes down to one critical element: comprehensive duct shop drawings.

These detailed technical documents serve as the blueprint for ductwork fabrication and installation, bridging the gap between conceptual design and physical reality. For contractors, engineers, and project managers, understanding the role of duct shop drawings in HVAC planning can mean the difference between project success and costly setbacks.

What Are Duct Shop Drawings?

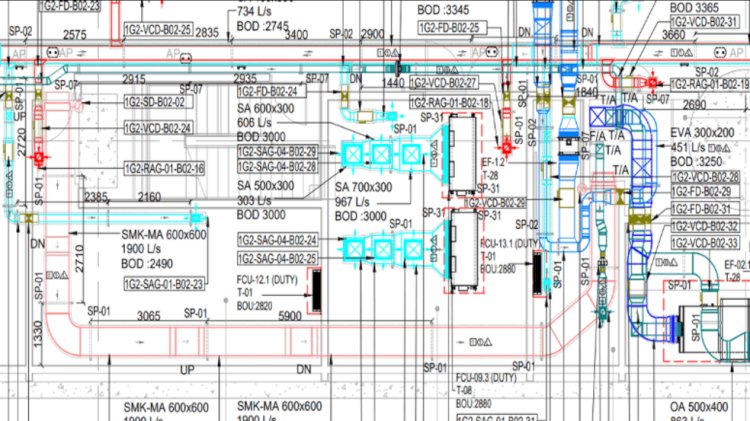

Duct shop drawings are detailed technical illustrations that show exactly how ductwork will be fabricated, assembled, and installed in a building. Unlike basic HVAC design drawings that provide general layout concepts, shop drawings offer precise specifications for every component.

These comprehensive documents typically include:

Dimensional specifications for each duct section, including length, width, height, and wall thickness

Connection details showing how ducts join together, including flange types and sealing methods

Support and hanger locations with load calculations and attachment specifications

Material specifications detailing gauge requirements, insulation types, and finish materials

Fabrication notes providing special instructions for cutting, forming, and assembly

The level of detail in duct shop drawings goes far beyond what's shown in architectural or mechanical drawings. They serve as manufacturing instructions for fabrication shops and installation guides for field crews, ensuring everyone involved in the project works from the same precise specifications.

Key Benefits of Duct Shop Drawings in HVAC Projects

Enhanced Accuracy and Reduced Field Errors

One of the most significant advantages of detailed duct shop drawings is their ability to eliminate guesswork during installation. When field crews have precise measurements and connection details, they can avoid the trial-and-error approach that often leads to delays and material waste.

Accurate shop drawings help prevent common installation problems such as:

- Ducts that don't fit in allocated spaces

- Misaligned connections between duct sections

- Conflicts with other building systems like electrical or plumbing

- Incorrect support placement that could cause system failure

Improved Project Coordination

HVAC systems must integrate seamlessly with other building components. Duct shop drawings facilitate this coordination by providing detailed spatial information that other trades can reference. This coordination becomes especially critical in complex commercial buildings where space is at a premium and multiple systems compete for the same areas.

Streamlined Fabrication Process

For sheet metal shops, detailed drawings eliminate ambiguity in the fabrication process. Workers can cut, form, and assemble ductwork components with confidence, knowing that each piece will fit perfectly when delivered to the job site. This precision reduces material waste and speeds up production timelines.

Better Cost Control

Accurate shop drawings enable more precise material takeoffs and labor estimates. Contractors can order exactly the right amount of materials and schedule labor more effectively, reducing both material waste and idle time on job sites.

How Shop Drawings Enhance System Performance

Beyond project management benefits, duct shop drawings directly contribute to HVAC system performance. Proper ductwork design affects airflow distribution, energy efficiency, and overall system effectiveness.

Optimized airflow paths can be designed when engineers have detailed spatial information, ensuring that air reaches all areas efficiently

Pressure drop calculations become more accurate when based on precise duct dimensions and connection details

Leak prevention improves when connection methods and sealing requirements are clearly specified

Maintenance access can be planned more effectively when duct placement and support systems are fully detailed

These performance improvements translate to long-term operational benefits, including lower energy costs and reduced maintenance requirements.

Modern Tools and Software

The creation of duct shop drawings has evolved significantly with advances in computer-aided design (CAD) and Building Information Modeling (BIM) software. Modern tools offer capabilities that were unimaginable just a few years ago.

CAD and BIM Integration

Current software platforms can automatically generate shop drawings from 3D building models, ensuring consistency between design intent and fabrication details. This integration reduces the time required to produce drawings while improving accuracy.

Automated Clash Detection

Advanced software can identify conflicts between ductwork and other building systems before construction begins, allowing designers to resolve issues in the planning phase rather than during expensive field modifications.

Material Optimization

Some programs can analyze ductwork layouts to minimize material waste and optimize cutting patterns, leading to cost savings and reduced environmental impact.

Future Trends in Duct Shop Drawings

The HVAC industry continues to embrace new technologies that promise to make duct shop drawings even more valuable in project planning and execution.

Augmented reality applications are being developed that can overlay shop drawing information onto real-world job sites, helping installers visualize exactly where components should be placed.

Prefabrication coordination is becoming more sophisticated, with shop drawings serving as the foundation for off-site assembly of large ductwork sections.

Performance modeling integration allows engineers to simulate system performance based on shop drawing specifications, optimizing designs before fabrication begins.

Mobile accessibility ensures that shop drawings are available to field crews on tablets and smartphones, providing instant access to critical information during installation.

Maximizing HVAC Success Through Detailed Planning

The role of duct shop drawings in efficient HVAC planning cannot be overstated. These detailed documents serve as the foundation for successful project execution, providing the precision and clarity needed to transform design concepts into functional reality.

For HVAC professionals looking to improve project outcomes, investing in comprehensive shop drawing development pays dividends through reduced errors, improved coordination, and enhanced system performance. As the industry continues to embrace new technologies and methods, the importance of detailed planning through quality shop drawings will only continue to grow.

The most successful HVAC projects share a common characteristic: they begin with thorough planning that leaves nothing to chance. Duct shop drawings provide exactly this level of detail, ensuring that every component, connection, and installation requirement is clearly defined before work begins.

What's Your Reaction?