How Well Do Nash Liquid Ring Vacuum Pumps Perform Across Different Industries?

Vacuum technology is an indispensable part of various commercial strategies, making sure efficiency, reliability, and precision. Among the various alternatives available, liquid ring vacuum pumps are extensively identified for their versatility and overall performance throughout exclusive sectors. In this weblog, we’ll explore how those pumps perform in a variety of industries, their advantages, and the characteristic of supporting device like shell & tube warm temperature exchangers in optimizing enterprise operations.

Understanding Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps characteristic on a easy but effective precept. These pumps create a vacuum by using manner of squeezing fuel the use of a liquid seal, commonly water or some other well matched fluid. The specific layout minimizes friction, ensuring sturdiness and reliability beneath hard situations.

Key benefits of liquid ring vacuum pumps consist of:

High tolerance for coping with wet, dusty, or corrosive gases.

Consistent performance even in harsh environments.

Low preservation and extended operational existence.

Applications of Liquid Ring Vacuum Pumps Across Industries

Let’s dive into the particular industries where liquid ring vacuum pumps play a vital position, ensuring clean and green operations.

- Chemical and Pharmaceutical Industries

The chemical and pharmaceutical sectors depend closely on specific vacuum situations for processes consisting of distillation, drying, and evaporation. Nash liquid ring vacuum pumps excel in these packages due to their capability to deal with aggressive and risky compounds. Their wet gas-coping with capability guarantees that even moisture-weighted down or corrosive vapors do now not preclude performance.

In addition, whilst paired with a shell & tube warmness exchanger, those pumps can efficaciously control heat transfer at some stage in chemical reactions, making sure balance and strength performance.

- Oil and Gas Industry

In the oil and fuel quarter, vacuum pumps are critical for vapor healing, gasoline compression, and wastewater treatment. Liquid ring vacuum pumps are in particular desired because they are able to tolerate fuel mixtures containing oil, water, and different impurities.

Their reliability in excessive environments and adaptableness to process necessities make them a desired choice in upstream and downstream operations. Furthermore, the usage of a shell & tube warmth exchanger along those pumps allows keep temperature manipulate, making sure most suitable pump overall performance and power conservation.

- Food and Beverage Industry

Vacuum systems play a crucial function in procedures like packaging, drying, and freeze-drying within the food and beverage enterprise. Liquid ring vacuum pumps stand out because they could deal with sensitive products without contamination dangers. These pumps ensure consistent vacuum ranges required for sealing and keeping freshness in packaged items.

Additionally, incorporating a shell & tube warmth exchanger can assist preserve the suitable temperature needed at some stage in manufacturing, enhancing product satisfactory and extending shelf existence.

- Pulp and Paper Industry

In the pulp and paper industry, liquid ring vacuum pumps are used for dewatering, forming, and pressing techniques. These pumps are highly green in putting off excess water from paper pulp, a vital step in achieving the favored paper exceptional.

The capability of liquid ring pumps to handle water-weighted down approaches without put on and tear ensures their durability on this demanding application. Supporting device like shell & tube warmth exchangers helps regulate temperatures inside the system, in addition enhancing power performance.

- Power Generation

Power plantations frequently depend upon vacuum systems for condenser evacuation and steam turbine sealing. Liquid ring vacuum pumps offer the important reliability and performance, even in continuous operation.

By pairing those pumps with a shell & tube warmness exchanger, power flowers can optimize warmth recuperation structures, decreasing power waste and enhancing typical plant efficiency.

- Textile Industry

In fabric manufacturing, strategies like dyeing, drying, and spinning require particular vacuum control. Liquid ring vacuum pumps make sure consistency and reliability in maintaining vacuum ranges, enabling clean operations and amazing output.

Their capacity to deal with wet and infected gases makes them ideal for this enterprise, in which moisture and residue are commonplace challenges.

Advantages of Liquid Ring Vacuum Pumps Over Other Technologies

Liquid ring vacuum pumps have received reputation throughout numerous industries for numerous reasons. Here’s how they compare to different vacuum technologies:

- High Tolerance for Contaminants

Unlike other vacuum pumps, liquid ring pumps can deal with drinks, gases, and stable particles with out full-size wear. This feature makes them perfect for industries handling complex or impure gasoline mixtures.

- Energy Efficiency

When used with helping device like a shell & tube warmness exchanger, liquid ring vacuum pumps can get better and reuse power, lowering overall operational prices.

- Durability

Their simple layout and minimum transferring elements ensure lengthy-time period reliability and low preservation requirements, making them a value-powerful preference for industries with demanding techniques.

- Versatility

From food processing to grease refining, liquid ring vacuum pumps adapt to a huge variety of programs, proving their versatility across industries.

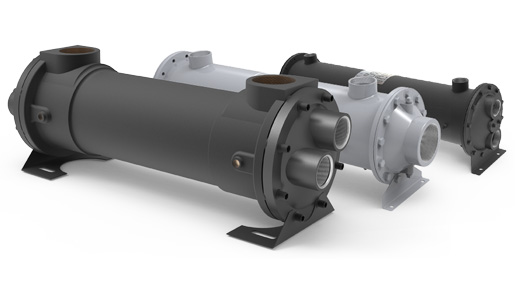

Role of Shell & Tube Heat Exchangers in Supporting Liquid Ring Vacuum Pumps

While liquid ring vacuum pumps are tremendously green on their own, their performance may be in addition enhanced through integrating a shell & tube heat exchanger into the device. This equipment plays a key role in:

Heat Recovery: Capturing waste warmth and reusing it in other methods, improving strength efficiency.

Temperature Regulation: Maintaining top-rated operating temperatures to make certain constant pump performance.

System Protection: Preventing overheating, that may result in gadget damage and downtime.

By combining those two technology, industries can obtain better tiers of productiveness, reliability, and sustainability.

Maintenance Tips for Liquid Ring Vacuum Pumps

To ensure the toughness and performance of liquid ring vacuum pumps, ordinary maintenance is critical. Here are some key hints:

Monitor Fluid Levels: Regularly check and refill the sealing fluid to maintain pump performance.

Inspect Components: Periodically investigate impellers, seals, and other parts for signs of wear or harm.

Clean the System: Remove debris and contaminants that would affect pump operation.

Use Compatible Materials: Ensure that the sealing liquid and substances used are well matched with the gases being treated.

Conclusion

Nash liquid ring vacuum pumps have verified to be an invaluable asset across numerous industries. Their ability to deal with tough situations, paired with the help of system like shell & tube warmness exchangers, guarantees greatest overall performance and electricity performance. Whether it’s in chemical processing, energy generation, or food manufacturing, these pumps provide dependable answers for important programs.

What's Your Reaction?