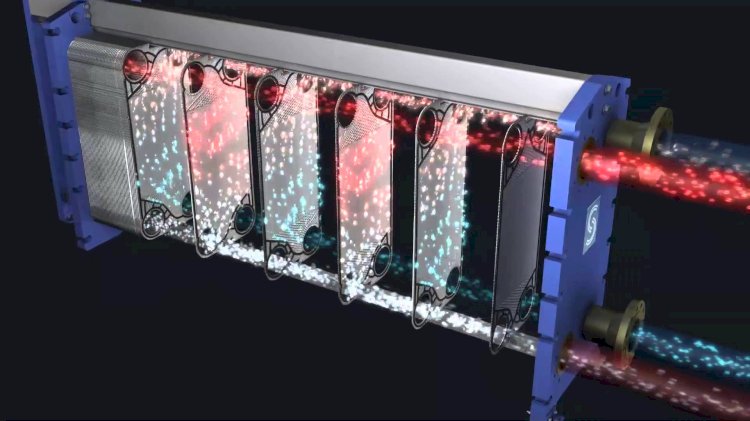

Plate Heat Exchanger Service Checklist: Fluids, Seals, Pressure, and Cleaning

Introduction: Don't Let Your Heat Exchanger Fail Unexpectedly

Heat exchangers are the unsung heroes of thermal systems in power plants, refineries, chemical processing units, and HVAC systems. Whether you rely on a plate heat exchanger, a finned heat exchanger, or another design, poor maintenance can lead to performance losses, system downtime, or even complete failure.

That’s where a structured heat exchanger service checklist comes into play. At Optimax, we deliver reliable and comprehensive plate heat exchanger services tailored to each system’s needs - and we know exactly what to look for during maintenance.

Why Regular Heat Exchanger Maintenance Is Critical

Over time, heat exchangers suffer from:

- Fouling and scaling that reduce thermal efficiency

- Gasket and seal degradation leading to leaks

- Pressure issues affecting safety and system performance

- Corrosion and external wear, especially in exposed environments

A preventive maintenance program ensures optimal efficiency, energy savings, and extended equipment life. Below is the essential checklist we follow to keep your plate and finned heat exchangers in top working condition.

Plate Heat Exchanger Service Checklist

1. Fluid Inspection and Analysis

- Check for contamination in heat transfer fluids

- Monitor pH and chemical balance in closed-loop systems

- Identify scaling, corrosion, or biofouling risks through fluid sampling

Clean fluids mean better thermal transfer and fewer deposits.

2. Seal and Gasket Condition

- Inspect for leaks, warping, or hardened gaskets

- Ensure seals still maintain elasticity and pressure tolerance

- Re-gasket plates as needed using OEM-approved materials

Gasket failure is one of the most common causes of exchanger leaks.

3. Pressure Testing

- Conduct hydrostatic or pneumatic pressure tests

- Compare readings to design specifications and historical baselines

- Identify pressure drops that may signal internal blockages or leaks

Regular testing prevents system failure due to unnoticed internal faults.

4. Plate Cleaning & Descaling

- Disassemble and clean plates manually or chemically

- Remove scaling, rust, oil, and biological growth

- Use non-destructive cleaning agents compatible with plate materials

Clean plates ensure optimal heat transfer efficiency and lower energy use.

5. Plate Condition and Alignment

- Inspect for plate deformation, cracks, or wear patterns

- Check plate alignment in the frame to ensure sealing surface integrity

- Replace any damaged or corroded plates

Even minor misalignment can lead to gasket blowouts or uneven flow.

6. Frame Inspection and Structural Integrity

- Inspect tightening bolts, carrying bars, and end frames

- Look for corrosion, especially on exterior frames in coastal or humid areas

- Apply protective coatings when needed (see below)

Bonus: External Protection with Sandblasting and Painting Services

Plate and finned heat exchangers in outdoor or corrosive environments require more than internal maintenance. At Optimax, we provide sandblasting and painting services to protect your equipment externally:

- Sandblasting removes rust, scale, and old coatings from exchanger frames

- Industrial-grade coatings are applied to protect from weather, salt, and chemical exposure

- Ideal for exchangers installed in plants across Texas, Portland, and the Gulf Coast

External protection ensures your investment lasts - inside and out.

Why Choose Optimax for Heat Exchanger Services?

At Optimax Services & Supply LLC, we offer:

- Comprehensive plate and finned heat exchanger services

- Skilled technicians trained in OEM and custom units

- On-site and in-shop servicing options

- Integrated sandblasting and industrial coating solutions for long-term protection

Industries We Serve

We support facilities across industries such as:

- Oil & Gas

- Power Generation

- Petrochemical

- Marine & Offshore

- Food Processing

- Water Treatment

Conclusion: Prevent Problems Before They Start

Routine inspections and cleaning aren’t just about maintenance - they’re about preventing catastrophic failure. A proactive approach to plate heat exchanger services ensures higher system efficiency, longer equipment life, and safer operations.

From fluid testing and pressure checks to seal replacement and external painting, Optimax delivers everything you need under one roof.

Book Your Next Heat Exchanger Service Today

Ensure your equipment is ready for the next cycle. Contact Optimax Services & Supply LLC for a custom inspection or to schedule heat exchanger services that keep your systems performing at their best.

What's Your Reaction?