Precision Manufacturing's Cornerstone: Swiss Screw Machining

Demand for smaller components, tighter tolerances, and sophisticated geometries has exploded in the changing realm of contemporary production. Industries like aerospace, medical, automotive, and electronics depend on complex components that have to be just perfect. Swiss screw machining is a somewhat specific process at the core of this precision-driven revolution.

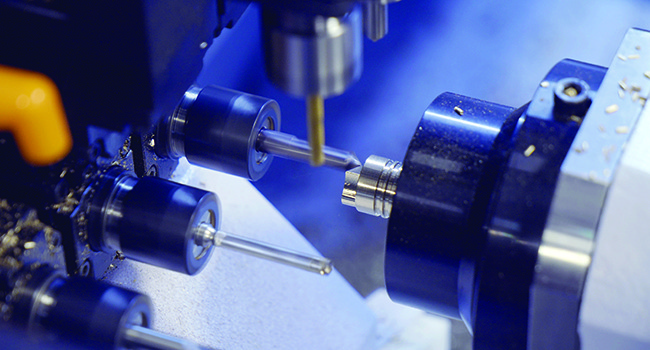

Also referred to as Swiss-type turning, this technique is redefining what small-part production can do. Commonly called Swiss turn parts, Swiss machines have set the gold standard for manufacturing high-quality, tight-tolerance components by including CNC precise turning capabilities.

A Synopsis of Swiss Screw Manufacturing History

Originally supporting the growing watchmaker sector, Swiss screw machining began in Switzerland in the late 19th century. Precision was first priority, and conventional equipment lacked the minuscule tolerances needed. Designed to meet this difficulty, the Swiss-type lathe let watchmakers create minute, complex components with amazing regularity.

Today, Computer Numerical Control (CNC) technology has fundamentally changed the ideas of Swiss machining. For CNC precise turning on a tiny scale, this junction of time-honored mechanics and contemporary automation has opened new opportunities.

Describes Swiss screw machining.

Using a sliding headstock and guiding bushing system, Swiss screw machining perfectly shapes tiny, complicated pieces. While the tools stay fixed in conventional lathes, with Swiss lathes the material moves. This technique reduces deflection, enabling rather tight tolerances—even on long, thin components.

Swiss machines are distinguished by their capacity for many operations within a single configuration. From turning and drilling to milling and threading, Swiss lathes can finish items in one cycle, therefore lowering handling time and raising general efficiency.

Using CNC Precision Turning in Swiss Machining

By stressing precision, repeatability, and automation, CNC (Computer Numerical Control) technology has transformed the industrial scene. CNC precision turning is very important in the framework of Swiss machining.

Multi-axis CNC controls used in modern Swiss machines provide for simultaneous cutting on many sides of a workpiece. This capacity guarantees every component satisfies rigorous dimensional constraints and dramatically lowers cycle times. Integration of CNC precise turning also means that little mistake may produce complicated geometries and features like undercuts, cross-drilled holes, and elaborate profiles.

Essential Benefits of Swiss Screw Machining

1. Unmatched accuracy

Swiss screw machining's capacity to maintain rather tight tolerances is one of its strongest suit. For sectors like aerospace engineering and medical device manufacture that need for great precision, this makes it the perfect method.

2. Perfect for Complex, Small Parts

Swiss lathes shine in creating tiny, intricate, and detailed Swiss turn components. Multiple machining processes within one cycle guarantees that items may be produced more effectively without compromising quality.

3. Perfect Surface Finish

Swiss machines may keep tight control over the cutting tool and the material by means of the guiding bushing, therefore producing a smoother surface finish. Secondary procedures and post-processing are thus less necessary.

4. Excellent Production Effectiveness

High- volume manufacturing runs notably benefit from Swiss screw machining. Mass production finds this cost-effective option as CNC automation combined with multi-tasking features greatly lowers setup and cycle times.

5. Minimized Tool Wear

The workpiece is constantly supported at the cutting region, hence there is less vibration and tool deflection, which increases tool life and guarantees constant performance over time.

Uses of Swiss Turn Parts

Because of their accuracy and dependability, Swiss turn parts find use in many different fields. Among the most often used ones are:

- Medical instruments include dental implants, surgical tools, bone screws.

- Aerospace: Control pins, sensor houses, fuel system parts

- Electronics: micro-screws, contacts, connections

- Automotive: Fasteners, valve components, transmission pins

- Defense: Guidance parts and precision firing pins

These sectors mostly depend on CNC precision turning to guarantee that their components satisfy safety and performance criteria.

Resources Applied in Swiss Screw Machining

Based on the intended use, Swiss machines may operate with a broad spectrum of materials. Typical materials include: stainless steel

- Aluminum

- Ti-strength

- brass

- Plastics, such as Delrin and PEEK

- Alloys (such as Hastelloy, Inconel)

The intended properties—such as corrosion resistance, strength, or biocompatibility—often determine the materials used.

When should one choose Swiss Screw Machining?

Every component cannot always be solved using Swiss machining. Still, it thrives in situations where tight tolerances—±0.0001 inches or better—are required.

- Generally speaking, parts have modest diameters—usually less than 1.25 inches.

- There is a desired high volume of output.

- Machining complex features in one operation is required.

Swiss machining coupled with CNC precision turning is usually the most effective and reasonably priced option for products that satisfy these characteristics.

Swiss Screw Machining: Looking Forward

Swiss screw machining seems to be bright as technology develops. Tool design innovations, real-time monitoring, and adaptive machining systems are stretching the boundaries of what's practical. Even more automation promised by improved CNC software and AI integration will help Swiss turn component manufacture quicker, smarter, and more exact.

Furthermore, the growing need for minuscule components in sectors such wearable technology, minimally invasive surgery, and micromechanics guarantees Swiss machining will always be a great benefit in precision manufacture.

Last thoughts

Foundation of precision production, Swiss screw machining combines modern CNC technology with century-old mechanical ideas. This method is a major facilitator of creativity in many high-tech sectors as it can generate complex Swiss turn pieces with amazing precision and efficiency.

Investing in CNC precision turning via Swiss machining may provide the quality and repeatability you want whether you are building components for the next-generation medical implant or aircraft system. Swiss machining is still the best choice for precision-oriented production in a world where every micron matters as it provides unrivaled performance.

Back to home:

What's Your Reaction?