What Makes Chop Saw Measuring Systems User-Friendly in 2025?

In the fast- paced world of construction, woodworking, and manufacturing, effectiveness and delicacy are at the core of every successful design. The ultramodern Chop saw measuring system has evolved dramatically in 2025, offering professionals and potterers tools that simplify cutting processes while enhancing perfection. These advancements have shifted stoner prospects from introductory measuring backing to intuitive, adaptable, and intelligent systems that reduce crimes and save time. The following points punctuate what makes these systems more stoner-friendly than ever ahead.

1. Intuitive Digital Interfaces

One of the most significant advancements in 2025 is the rise of largely intuitive digital interfaces. Traditional chop saw systems frequently needed primer adaptations that could be confusing for newcomers. Now, ultramodern interfaces point to touchscreens, clear icons, and step- by- step prompts. These design choices make it simple for druggies to input measures, elect cutting modes, and confirm settings without expansive training. The digital display also ensures readings are clear indeed in dim lighting, removing nebulosity and reducing miscalculations.

2. Flawless Integration with Design Software

stoner- benevolence moment also stems from the capability of measuring systems to integrate directly with design and modeling software. Numerous systems can now connect to CAD programs, transferring measures incontinently without homemade recap. This reduces the threat of mortal error and ensures that systems move from digital planning to physical prosecution seamlessly. For professionals managing complex designs, this integration eliminates time- consuming recalculations and streamlines workflows, making the chop saw system easier to use across colorful operations.

3. Automated Adaptations for Accuracy

ultramodern chop saw measuring systems are designed to automatically acclimate cutting angles and lengths grounded on programmed inputs. Rather of druggies manually rechecking measures with every cut, the system recalibrates itself to insure thickness. This robotization is particularly helpful for repetitive tasks where perfection is critical. The ease of robotization has made these tools more accessible to new druggies while still serving the demands of educated professionals who calculate delicacies for large- scale systems.

4. Ergonomic Designs for Comfort

Ergonomic design has become a central focus in 2025, making chop saw measuring systems physically easier to operate. malleable daises, reduced vibration technology, and precisely deposited controls allow druggies to work longer without discomfort. Handles and adaptation regulators are frequently designed with stoner comfort in mind, icing they're accessible and bear minimum trouble to use. These advancements reduce fatigue and make the systems friendlier for both educated tradesmen and beginners likewise.

5. Voice Command Capabilities

One of the most innovative features enhancing stoner- benevolence is the relinquishment of voice command functionality. Rather than manually conforming settings, druggies can now issue verbal instructions to set measures or modify angles. This hands-free approach allows workers to stay focused on the material they're cutting, saving precious time and perfecting safety. Voice recognition technology has advanced to a point where it can understand different accentuations and speech patterns, making it practical for wide use.

6. Real- Time Feedback and Error Discovery

Another factor that makes chop saw measuring systems easier to use is real- time error discovery. Advanced detectors can now warn druggies incontinently if a dimension is out or if a cut does n't align with the programmed specifications. This moment feedback reduces wasted accoutrements and helps newcomers correct miscalculations snappily. Numerous systems also give suggestions for adaptations, icing that indeed those strange with specialized details can still achieve precise results.

7. Portability and Snippersnapper Designs

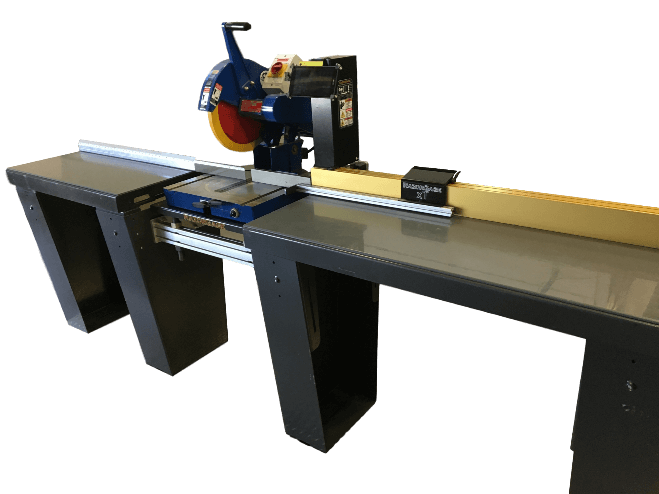

In former times, chop saw measuring systems were frequently big and delicate to transport, limiting their inflexibility. The 2025 designs have concentrated heavily on portability, making them lighter without compromising continuity. Foldable daises, modular attachments, and compact measuring arms make the systems more mobile, enabling workers to bring them directly to job spots with minimum trouble. The convenience of portability has made these systems more charming to a wider followership, adding usability across different diligence.

8. Energy Efficiency and Sustainability

stoner- benevolence is n't only about direct functionality but also about how well a system adapts to ultramodern enterprises similar to sustainability. Today’s chop saw measuring systems are erected with energy effectiveness in mind, consuming lower power and generating smaller emigrations. Numerous incorporate eco-friendly accoutrements while maintaining long- lasting continuity. For druggies, this translates to lower operating costs and the assurance that they're working with environmentally responsible technology, which is an added subcaste of convenience in moment’seco-conscious request.

9. Enhanced Safety Features

Safety is a crucial factor in making any tool stoner-friendly, and 2025 systems exceed in this regard. Hash saw measuring systems now come equipped with advanced safety mechanisms similar as automatic blade stops, stir detectors, and defensive walls. These features minimize the threat of accidents and give druggies confidence while working. Indeed those with limited experience can operate the system safely thanks to clear visual cautions and automatic arrestment capabilities when unsafe conditions are detected.

10. Rigidity for Different operations

Maybe the most defining factor in stoner- benevolence is rigidity. ultramodern systems are no longer limited to a narrow set of tasks. Rather, they're designed to handle a wide range of accoutrements and slice conditions. From woodworking and essence fabrication to construction and custom systems, these systems can acclimatize their settings automatically to suit the material being cut. This versatility eliminates the need for multiple tools, simplifying the stoner experience and icing the system remains applicable for varied operations.

Conclusion

By 2025, chop saw measuring systems have become more than just tools for accurate dimension — they have converted into comprehensive, intelligent systems that prioritize the stoner experience. With features like intuitive digital interfaces, voice command capabilities, error discovery, ergonomic designs, and flawless software integration, they feed to both professionals and newcomers alike. Their rigidity, portability, and advanced safety norms ensure they're practical and effective in a wide range of settings. As the assiduity continues to embrace robotization and invention, the elaboration of these tools highlights how convenience and perfection go hand in hand. For numerous reasons, these advancements not only simplify tasks but also pave the way for the future of cutting technology, particularly when integrated with an automatic saw system.

What's Your Reaction?