When and Where Should You Use Cable Pulling Lubricant? Expert Tips

Have you ever struggled with pulling cables through tight spaces and wondered if there’s an easier way to do it? Cable pulling can be a tough job, especially in long runs or crowded conduits. This is where cable pulling lubricant comes into play. It reduces friction, helps the cables glide smoothly, and prevents damage to the cable insulation or jacket. But when exactly should you use it, and in what situations does it make the most sense? Let’s break it down in simple terms with some expert tips.

Why is cable pulling lubricant important?

Pulling cables through conduits or ducts generates friction. If the friction is too high, it can damage the cable’s insulation, cause tears, or even break the cable. Lubricants act as a protective layer that makes the process smoother and safer. This means less effort for the workers and reduced chances of costly cable replacements. In short, using lubricant is like adding oil to a squeaky hinge – it makes everything move more easily and lasts longer.

When should you use cable pulling lubricant?

You don’t need lubricant for every single cable installation. For short and straight runs with minimal bends, you may not need it. However, if the cable run is long, has multiple bends, or passes through tight spaces, lubricant becomes essential. For example, pulling a cable through a 50-meter conduit with several curves will almost always require lubrication. Another time to use it is when cables have thick jackets or heavy bundles, as these add more resistance during the pull.

Where does cable pulling lubricant work best?

Lubricant is most effective in conduits that have bends, rough interiors, or are crowded with multiple cables. It can also be helpful in underground ducts where the conditions are harsh, and friction can quickly damage the cable. For example, installing electrical cables under roads or industrial sites often involves pulling through long, rugged ducts, making lubrication a must. Even overhead cable installations with pulleys and sheaves can benefit from reduced friction, ensuring that cables don’t get scuffed or stretched.

How do you apply cable pulling lubricant properly?

Using lubricant isn’t just about pouring it randomly. There are proper methods for applying it to get the best results. Start by coating the cable evenly before it enters the conduit. You can also apply lubricant directly inside the conduit in some cases. Make sure you don’t use too much, as excessive lubricant can create a mess and attract dirt later. For large jobs, special pumps and feeders are available to apply lubricant consistently. Always follow the manufacturer’s instructions for best results.

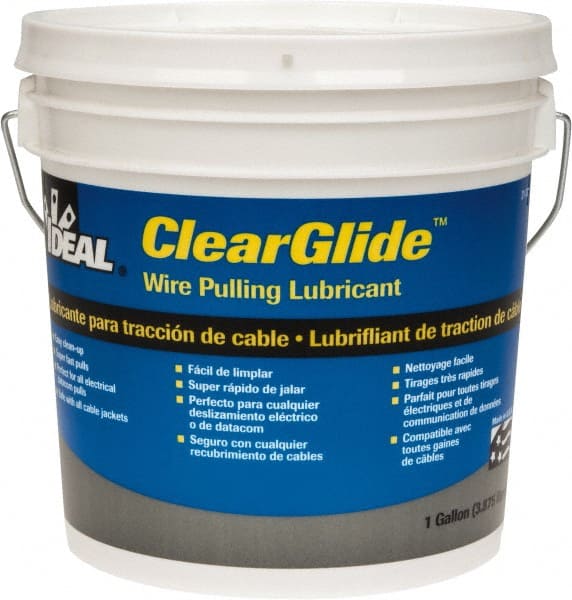

What type of lubricant should you use?

Not all cable pulling lubricants are the same. Some are gel-based, others are wax-based, and some are liquid. Each type is designed for different conditions. For example, gel lubricants are great for vertical or overhead pulls since they stick better and don’t drip. Wax-based lubricants are more suitable for heavy-duty or high-temperature applications. Choose a lubricant that is compatible with the cable’s material and safe for the environment.

What safety measures should you take while using it?

While lubricants make the job easier, safety is still important. Make sure the lubricant is non-toxic and non-flammable, especially when working in enclosed spaces. After the pull is complete, wipe off any excess lubricant from the cables to keep the area clean and reduce the chance of dirt buildup. These simple practices can keep the job site safe and professional.

How does using lubricant save time and money?

When cables get damaged due to friction, it leads to extra costs for repairs and replacements. It can also delay projects. Using lubricant helps avoid these issues by making the pulling process faster and smoother. Less force is needed, which also reduces strain on workers and equipment. In the long run, investing in good-quality lubricant pays off by improving efficiency and extending the life of your cables.

Conclusion

Cable pulling lubricant isn’t needed for every installation, but when you have long runs, multiple bends, or tough conditions, it can make all the difference. It reduces friction, protects the cables, and saves time and money. By using the right type of lubricant and applying it correctly, you can make your cable pulling jobs safer and more efficient. Next time you’re planning a cable installation, ask yourself: Will lubricant make this easier and safer? Chances are, the answer will often be yes.

What's Your Reaction?